Wedoany.com Report-Oct. 30, The second steam generator for the nuclear island at unit 1 of the Lianjiang nuclear power plant in Guangdong province, China, has been installed. This step completes the placement of major equipment for the unit.

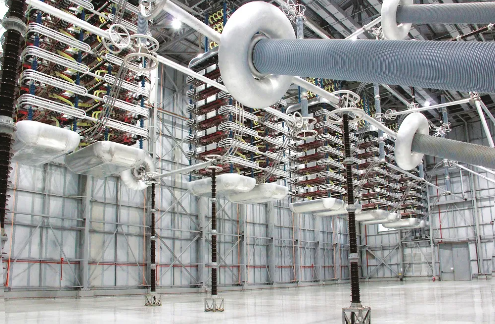

Steam generators function as heat exchangers that transform thermal energy from the reactor core into steam. The steam travels through the main pipeline to the conventional island, where it powers the turbine connected to the electricity generator.

Construction of the initial pair of 1250 MWe CAP1000 reactors—China's adaptation of the Westinghouse AP1000 design—at the Lianjiang location received approval from the State Council in September 2022. Site excavation started that same month. First concrete for unit 1's base was poured in September 2023, followed by unit 2 in April 2024. Unit 1 is scheduled for completion and commissioning in 2028.

The reactor pressure vessel for unit 1 was positioned in February this year.

The placement of the second steam generator "completes the installation of key equipment, including the pressure vessel, steam generators, and pressuriser, for unit 1, laying a solid foundation for the completion of the primary circuit connection of the nuclear island reactor and the capping of the reactor building," Lianjiang Nuclear Power Company stated.

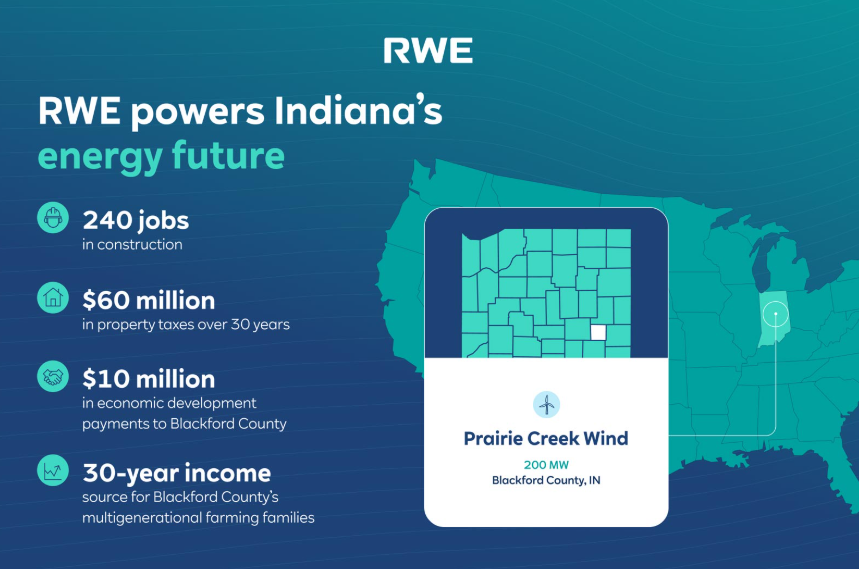

Upon full operation of all six planned CAP1000 units at the site, annual electricity output is projected at approximately 70.2 TWh. This would decrease standard coal usage by over 20 million tonnes, cut carbon dioxide releases by more than 52 million tonnes, lower sulphur dioxide by around 171,000 tonnes, and reduce nitrogen oxides by about 149,000 tonnes.

State Power Investment Corp indicates that the Lianjiang facility will be the first nuclear project in China to implement seawater secondary circulation cooling technology and the first to feature a super-large cooling tower.

These advancements support reliable energy production and environmental goals at the plant. The CAP1000 technology incorporates passive safety features for enhanced operational stability. Installation milestones ensure progress toward the 2028 target for unit 1.

The site's design optimizes heat dissipation through innovative cooling methods, contributing to efficient plant performance. Completion of core components allows subsequent phases, such as circuit connections and structural enclosures, to proceed on schedule.

Overall, the Lianjiang project represents a significant addition to nuclear capacity in the region, promoting sustainable power generation with reduced resource consumption and emissions.

京公网安备 11010802046720号

京公网安备 11010802046720号