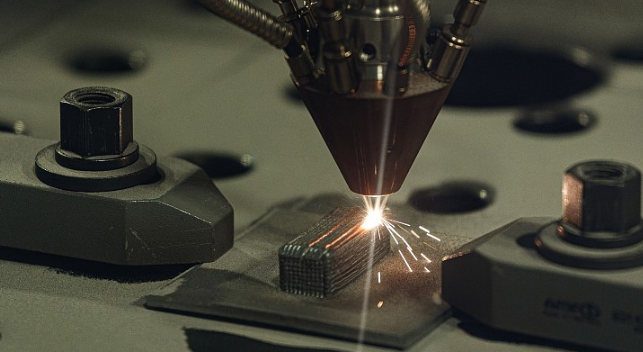

Wedoany.com Report-Nov. 30, Russia has received regulatory approval for the first reactor component produced using 3D printing for the RITM-200 small modular reactor series. The component, a terminal box, was manufactured by Afrikantov OKBM, a design bureau within state nuclear corporation Rosatom.

The RITM-200 reactors power Russia's latest nuclear icebreakers and form the basis for planned floating and land-based small modular reactor plants. The prototype terminal box successfully completed comprehensive testing, leading to the development and approval of supporting regulatory documentation and issuance of the first certificate by the Russian Maritime Register of Shipping.

Rosatom stated that the project provided valuable experience in applying additive manufacturing to reactor equipment, established necessary regulatory frameworks, and laid the groundwork for producing more complex and critical RITM-200 components using 3D printing in the future.

Yuri Vytnov, Chief Technologist at Afrikantov OKBM, said: "Obtaining regulatory documentation for the first product for the RITM-200 reactor plant, manufactured using additive technologies, allows for the future replication of 3D printing technology to create various equipment for ship nuclear power plants, as well as other types and purposes of nuclear industry equipment."

Ilya Kavelashvili, Director of the Additive Technologies Business Unit at Rosatom's Fuel Division, said: "The use of 3D printing opens up new possibilities for design and production. Parts with optimised geometry and improved characteristics can be created. This allows for increased efficiency and reliability of the equipment, as well as a reduction in weight and cost."

Additive manufacturing enables the creation of components that are difficult or impossible to produce through traditional casting or machining methods. It also reduces material use, weight, and production time. While 3D printing has previously been employed in Russia for test equipment and tooling: this marks its first application to certified reactor components.

The milestone aligns with growing international adoption of additive technologies in nuclear energy, with prior examples including components installed in reactors in Slovenia, the United States, and Sweden. Several countries, including South Korea and the United Kingdom, are also advancing similar applications. Rosatom's achievement demonstrates continued progress in integrating advanced manufacturing techniques into nuclear equipment production while maintaining strict regulatory and safety standards.

京公网安备 11010802046720号

京公网安备 11010802046720号